Rolls Royce Motor Cars are manufactured via a “bespoke” process on a mechanized and computerized assembly line, but most of this process of putting the components together are done by hand. A RR engine is put together usually by one person and by hand. It takes approximately three and a half months from order and deposit to delivery depending on production priorities. Order a limited production run, or one of the coupes, or any special edition that will be rare (ie “Centenary Edition” or “Phantom Black”), or a car that has been “tricked out” with lots of bespoke options (not on the options list but put in the car anyway, like an exclusive color or an extra refrigerator, or wood veneer in places it normally isn’t)–such cars take longer to delivery time, usually around 6 months, sometimes up to a year. The rarer the car the longer the time. Unlike other custom hand built car brands, often called “bespoke cars,” like Maybach or Bentley which can take longer to manufacture, The BMW owned and operated Rolls Royce Motor Car products, sold in the 2008 model year, as the Phantom SWB (Standard Wheelbase) or LWB (Long Wheelbase) Saloons, and the Phantom Fixed and Drop Head Coupes, take a little less time than other brands from order to finished hand assembly.

Rolls Royce Motor Cars are manufactured via a “bespoke” process on a mechanized and computerized assembly line, but most of this process of putting the components together are done by hand. A RR engine is put together usually by one person and by hand. It takes approximately three and a half months from order and deposit to delivery depending on production priorities. Order a limited production run, or one of the coupes, or any special edition that will be rare (ie “Centenary Edition” or “Phantom Black”), or a car that has been “tricked out” with lots of bespoke options (not on the options list but put in the car anyway, like an exclusive color or an extra refrigerator, or wood veneer in places it normally isn’t)–such cars take longer to delivery time, usually around 6 months, sometimes up to a year. The rarer the car the longer the time. Unlike other custom hand built car brands, often called “bespoke cars,” like Maybach or Bentley which can take longer to manufacture, The BMW owned and operated Rolls Royce Motor Car products, sold in the 2008 model year, as the Phantom SWB (Standard Wheelbase) or LWB (Long Wheelbase) Saloons, and the Phantom Fixed and Drop Head Coupes, take a little less time than other brands from order to finished hand assembly.

The video below shows how a Rolls Royce Phantom is made.

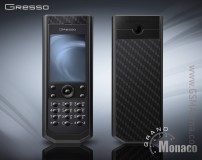

This post sponsored by:

Dr Mobiles Limited

1 Huron Street, Takapuna, North Shore 0622

Tel: (09) 551-5344 and Mob: (021) 264-0000

Web - Map - Google+ - Email - Posterous - Twitter - Blogger - Flickr - Author